TiSHX: The New Standard In Super Cub Shocks

Alaska holds some of the world's largest swaths of untouched earth and has inspired countless adventurers to push the limits and access raw country untouched by humans. At Alaska Gear Company, we pride ourselves on developing the tools to operate in the world's most remote and untamed backcountry environments.

Bush planes are the fastest and most effective way to penetrate deep into the backcountry. Flying off-airport opens up a world of freedom few have ever experienced, but it creates significantly more stress on the aircraft and requires a vastly more experienced pilot with specialized equipment to reach these untouched rough landing zones.

There's an old story of a hunting guide in Alaska who would take extreme measures to access unhunted terrain. He would scout areas with a dense moose population known to be inaccessible by aircraft. After finding an almost landable spot in a good moose area, he would crash-land the airplane and cut and clear a usable landing strip. Someone would then fly out, and they would recover the aircraft with a helicopter. He would then fly hunters in and out of the area during moose season, after which he would spend winter rebuilding the airplane to do it all over again the next spring.

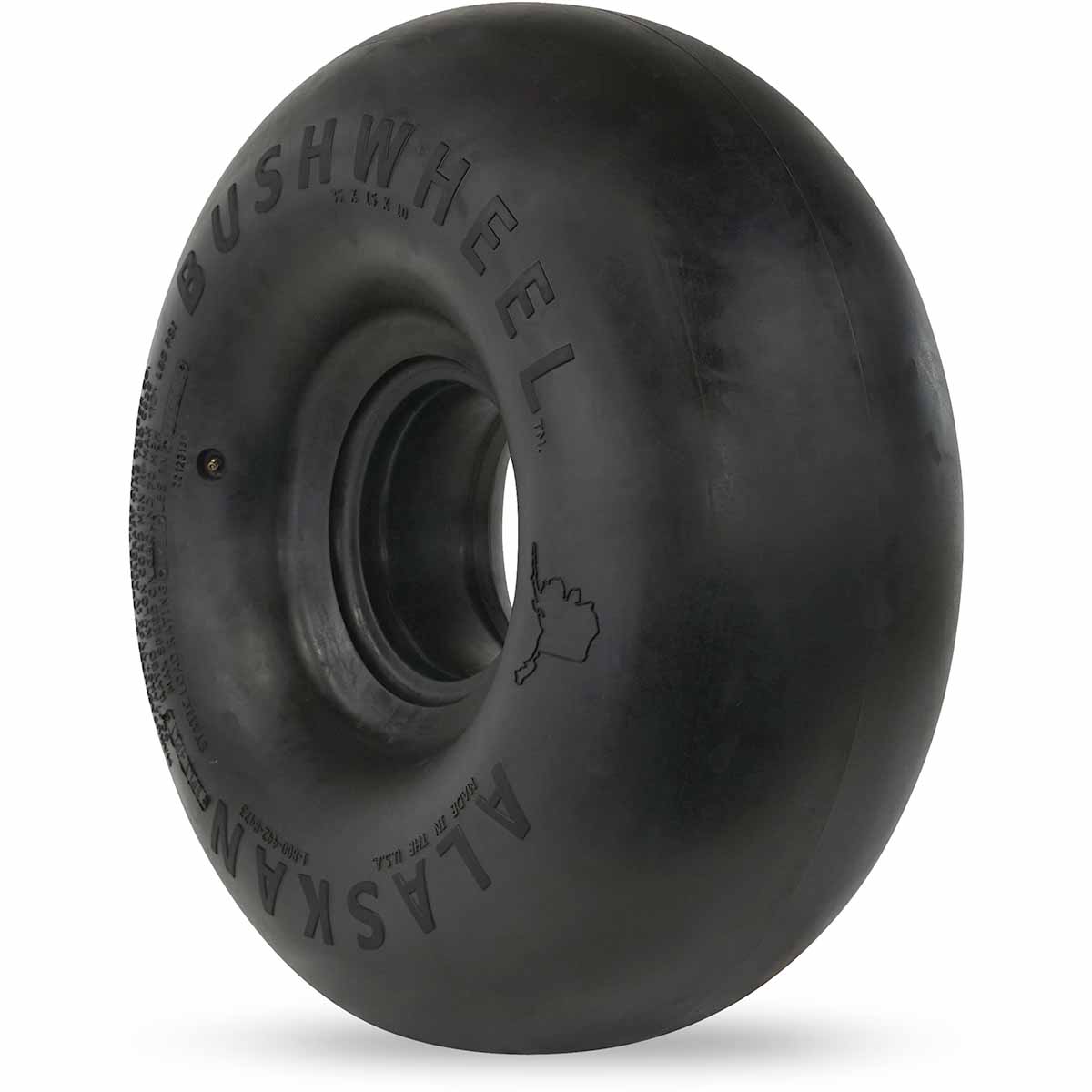

Since the old days, bush planes have become much more expensive and less expendable. We have gone to great lengths to improve the margin of safety in accessing these areas with equipment such as the extended heavy-duty landing gear, the iconic Alaskan Bushwheels, and now the TiSHX Super Cub Suspension System—the new standard in Super Cub Shocks.

Issues With The OEM Bungee Suspension

The original bungee-style suspension system had many well-known issues and often caused what bush pilots call "crow hopping," where you bounce several times back into the air after the initial touchdown. Crow hopping makes landings unpredictable and difficult to avoid hazards in the landing zone. This issue has led to the development of more sophisticated shock-style gas suspension systems, but none have reached the potential of what dirt bikes and off-road vehicle shocks have been able to accomplish.

The Alaska Gear Company saw this as an opportunity to extend backcountry accessibility further than the Alaskan Bushwheels. Alaska Gear Company CEO Sean McLaughlin set out to assemble a team he was confident could achieve this.

A Pilot First Approach To Design

Loni Habersetzer is one of the world's most experienced Super Cub pilots. He has dedicated his entire adult life to pushing the limits of where a Super Cub can land. He has recorded over 50,000 off-airport landings in challenging terrain such as narrow gravel bars, muddy bogs, and mountain slopes. Because of this, the Alaska Gear Company has long relied on Loni as a test pilot and expert in backcountry flying.

Alaska Gear Company took a pilot-first approach to develop this shock, and Loni's involvement in the project's conception greatly impacted its success. By designing a suspension system against a pilot who has dedicated his life to pushing the performance of the Super Cub as far as he can and is always pushing for more, we were confident we would be able to achieve the highest level of performance possible.

Perfecting The Valving

Valving issues was one of the first things we addressed in developing a high-performance gas shock that meets the full potential of the current technology. We enlisted Wayne Israelsen of Alltech Motorsports, the world's leading shock building and valving expert, to solve this. He specializes in off-road racing and is the go-to shock expert for many successful racers. He has helped many successful racers, including three-time King of the Hammers Shannon Campbell.

Enhancing The Spring

One of our initial design requirements was to create a system that could withstand the elevated number of cycles a professional bush pilot like Loni would encounter. We sent our first spring design to be evaluated by an engineering firm specializing in springs. They found that the initial spring diameter was too small, would fatigue, and be prone to failure after a limited number of cycles.

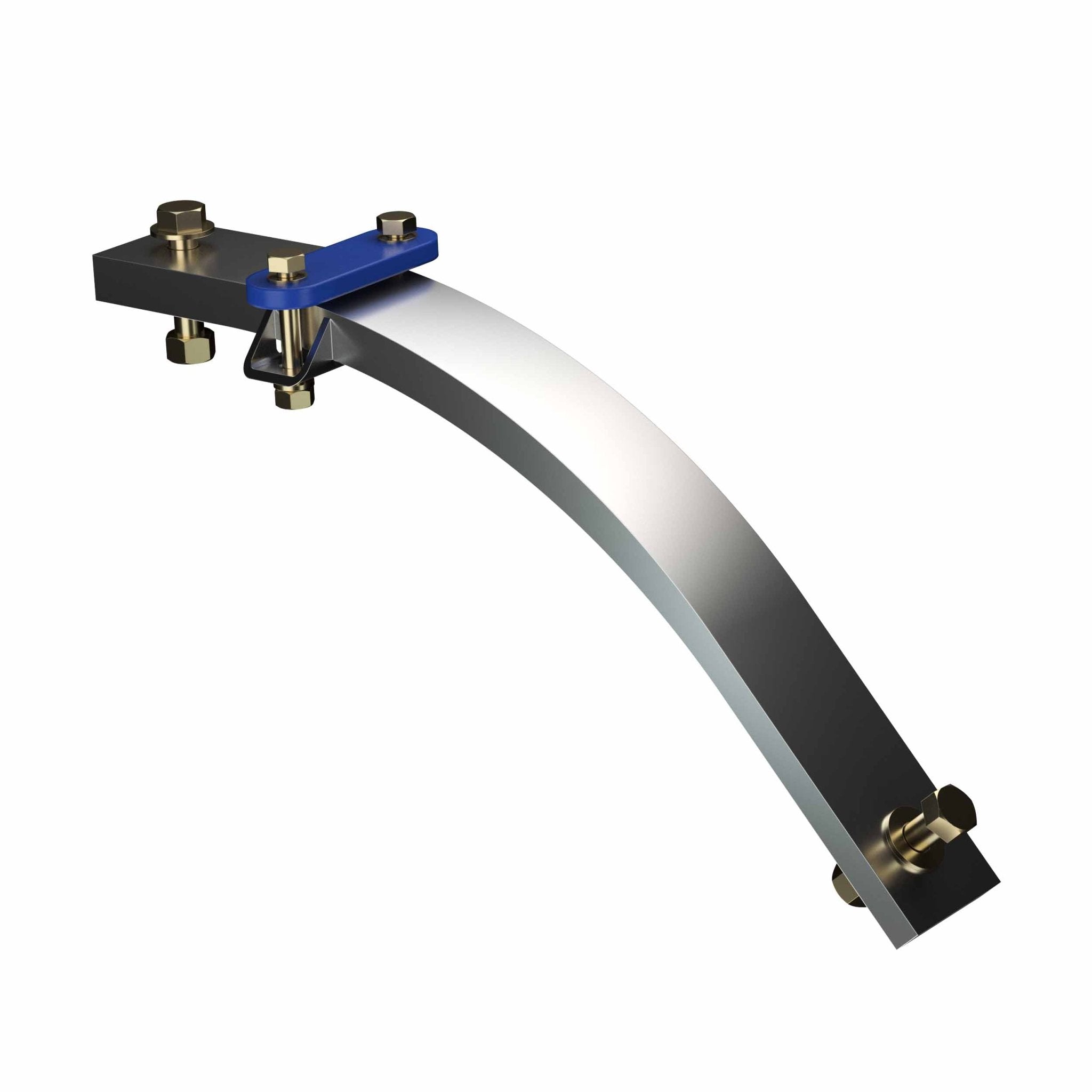

So, we developed a more robust spring to accommodate the gross weight of a 2,000-pound Super Cub. This expansion in length and diameter also meant we could set the initial preload to adjust the shock's firmness without limiting travel, creating smoother ground operations and preventing wing rock.

Another improvement we made was implementing a spring guide that protects the spring from making contact with the shock tube and prevents aluminum shavings from contaminating the oil. The spring guide also acts as a travel limiter, preventing the spring from going to coil bind, resulting in fatigue and stress on the system, eventually resulting in a catastrophic failure.

Balancing Weight and Performance

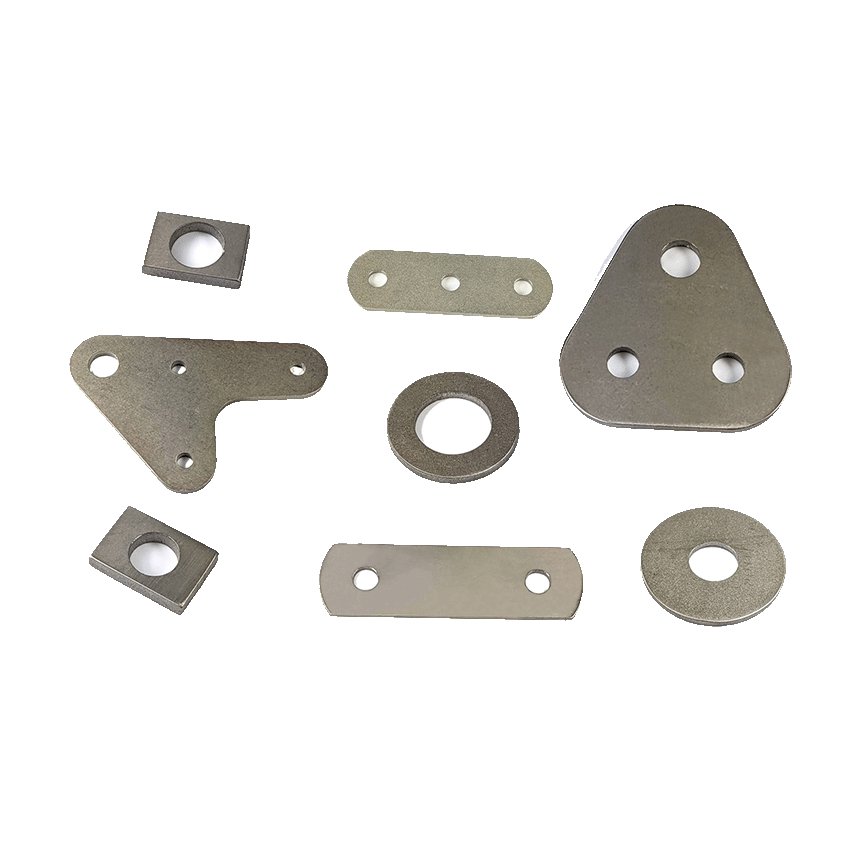

We determined that the best way to beef up the spring was to replace the rest of the system with lighter, high-performance materials. The only steel components in the system are the spring and the valve stack shims. By switching to titanium components, we could increase the diameter of the steel spring while still being within our target weight.

Sealing The Shock and Eliminating the Need for a Schrader Valve

The design features a free-floating internal piston and a chamber with a lifetime seal filled with three times the standard amount of compressed air, eliminating the need for the Schrader Valve. A common misconception of the Shrader valve is that it tunes the shock's performance by changing the amount of compressed air in the chamber. The reality is that with a shock of this size, the amount of compressed air in the system does not affect the spring's performance, such as the compression, rebound, or shock preload.

The compressed air in the system moves the piston back and forth to prevent cavitation but does not affect the firmness of the spring. The purpose of the Schrader valve changes slightly in lighter applications. But, in heavy-duty shocks for off-road vehicles and Super Cubs, the Schrader valve is used only to recharge the chamber with nitrogen due to a leak, an issue the TiSHX does not have.

Results From Field Testing

Last summer, after nearly five years, three iterations, and over 5,000 landings, we headed back to the Ultima Thule Lodge in the Wrangell Saint Elias mountains with Wayne Israelsen to do the final valving, and the results were extraordinary.

Field testing confirmed that we had successfully developed the best suspension system available for the Super Cub, opening up landings that our test pilot, Loni, would have previously considered unlandable.

Certifying with the FAA

We then completed the long and rigorous process of certifying the suspension with the FAA. After months of drop testing and engineering reports, we were awarded an STC and have started production at our facility in Palmer, Alaska.

The New Standard In Super Cub Suspension is Here

The TiSHX was brought to life by some of the greatest minds in the aviation and suspension world. It creates a safer, more controlled landing that reduces jarring forces on the fuselage and pilot. The TiSHX provides a newfound ease in hitting landing marks due to the absence of rebound and crow hopping and allows for precise control and directional braking, making ground maneuvers safer and more predictable.

Safe flying.