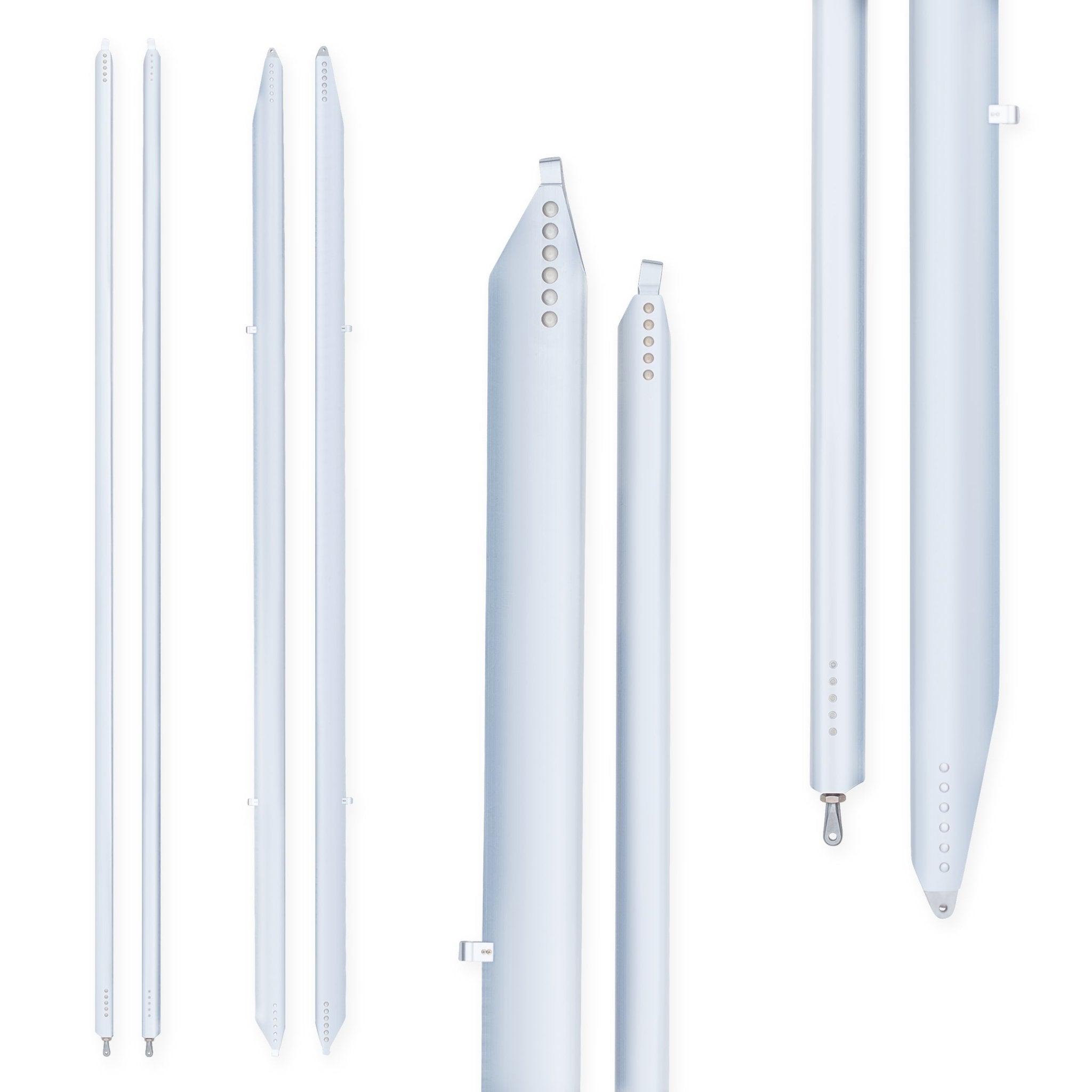

Details

The Husky Aluminum Lift Struts offer unmatched corrosion resistance, weight reduction, and increased strength compared to traditional steel struts. These struts outperform Heavy-Duty Steel Struts, providing a reliable and lightweight method of cutting weight.

Overview

Due to factors such as material costs, supply chain challenges, and design limitations, we have opted to discontinue the production of Sealed Steel Struts. Instead, we are now exclusively focusing on Aluminum lift struts. The design approach for the aluminum lift strut centers around two main aspects: corrosion resistance and weight reduction. This strategy has significantly boosted the popularity of aluminum lift struts, resulting in a continuous year-over-year increase in demand.

Corrosion Resistance

Originally, we developed and manufactured the sealed strut in response to the 99-01-05 Airworthiness Directive. This directive was issued due to concerns about moisture infiltration causing corrosion within the strut, imperiling its structural integrity. However, the design of the sealed strut was complex and heavy, especially when considering processes like powder coating.

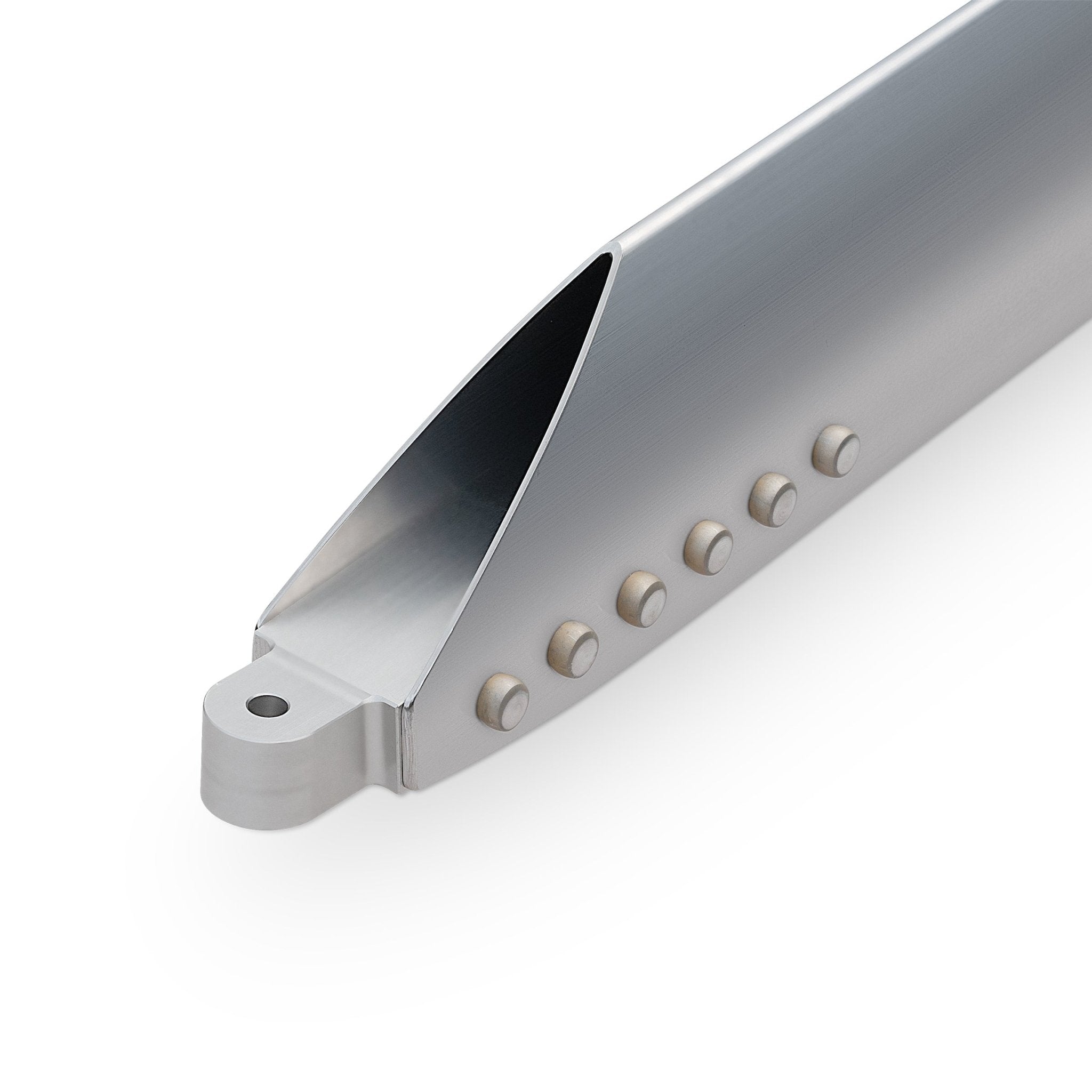

In contrast, the aluminum lift strut is entirely resistant to corrosion. It incorporates a simplified hollow design that prevents moisture entrapment and allows for straightforward inspections. Remarkably, these inspections are not mandatory for compliance with the 99-01-05 AD. Although the aluminum struts can be painted, painting is not obligatory.

Weight Reduction

One of the most significant advantages of aluminum is its superior strength-to-weight ratio. This translates to higher tensile strength and improved compression weight compared to the traditional steel struts. Additionally, the new aluminum struts are notably lighter, with potential weight savings of up to 9 lbs.

Increased Strength

Questions have arisen regarding the strength of the Aluminum Strut compared to the Heavy-Duty Steel Strut. Strut strength is assessed in terms of tension and compression. Tension pertains to the lift force exerted by the aircraft during flight, while compression refers to the weight on the wing while it's on the ground, like snow loads. Our certification tests with the FAA demonstrated substantial improvements. The front and rear struts showed a significant increase in tension strength, and the front strut exhibited a 50 lbs boost in compression strength, with the rear strut experiencing an impressive 400 lbs increase. These enhancements surpass the strength of the Heavy Duty Lift Strut.